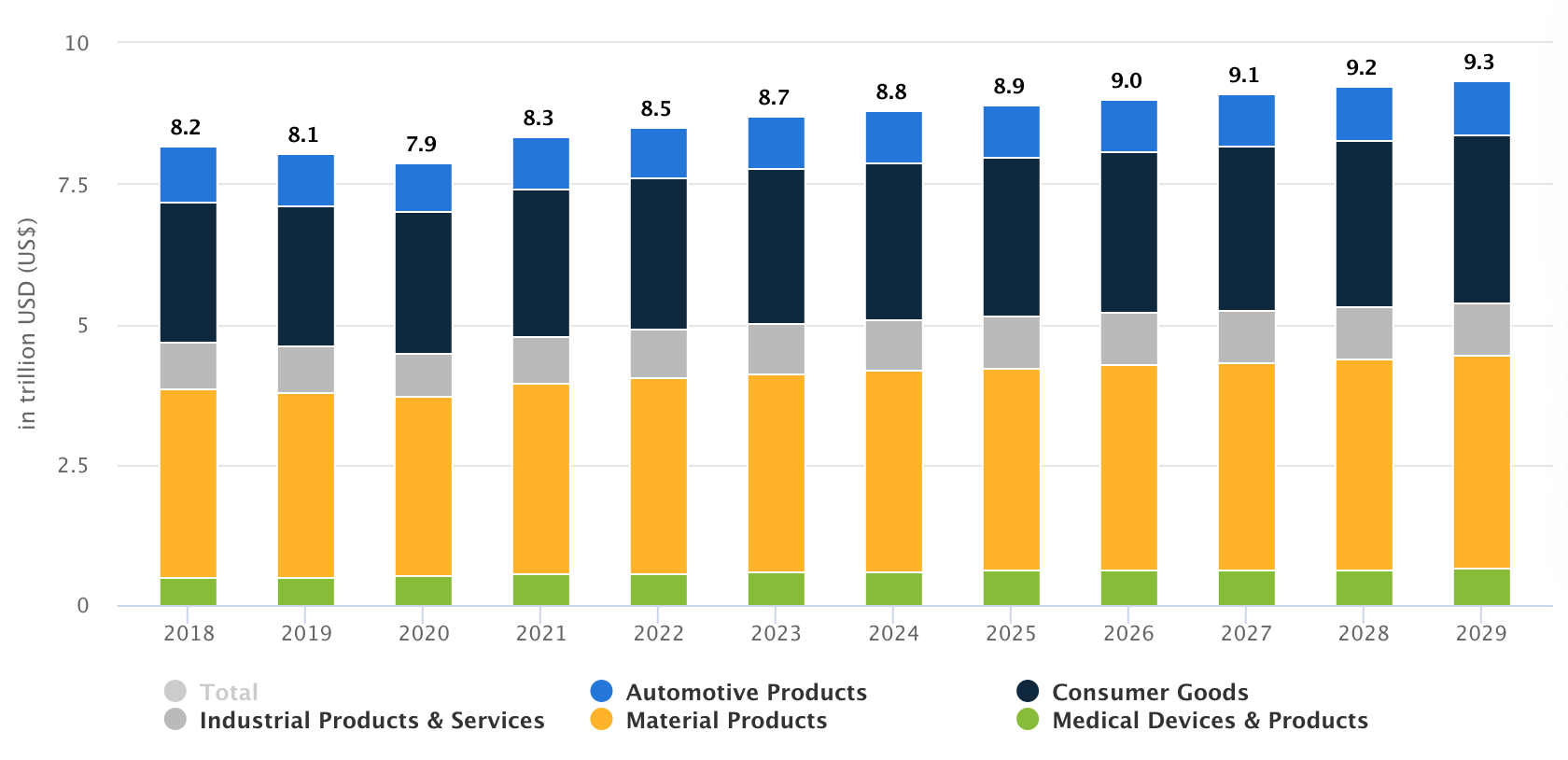

Manufacturing is among the large 4 that retains the worldwide financial system going, proper up there with providers, agriculture, and tech. And get this—Statista predicts the manufacturing market will hit an enormous $8.8 trillion by the top of 2024.

The worth of the manufacturing market in 2024, supply Statista.

Within the US alone, the variety of folks concerned in manufacturing is estimated at 12.7 million, to not point out international locations like China and India, the place the inhabitants is 10 occasions bigger than the inhabitants of the US.

The manufacturing sector covers all kinds of bodily items. This contains turning uncooked supplies or semi-finished merchandise into completed gadgets, plus establishing, putting, and repairing industrial equipment and gear.

Manufacturing is carefully intertwined with a bunch of various domains, like meals and drinks, textiles, chemical compounds, metalworking, and electronics. It’s a giant deal that touches on plenty of areas.

With such a dense and sophisticated nature, it’s no shock that manufacturing requires excessive expertise help, primarily artificial intelligence (AI) and machine learning, to refine bills, scale back waste, and enhance manufacturing course of effectivity.

This fashion, in the present day, we’ll go over seven main AI hacks your manufacturing firm can make use of instantly and see quick outcomes.

Why Trendy Manufacturing Can’t Do With out Excessive Applied sciences

Earlier than we plunge into the particular AI hacks in manufacturing, let’s take a step again and see how AI influences the sector and why it’s changing into essential instrument in fashionable manufacturing circumstances.

The trendy manufacturing atmosphere more and more suffers from the strain to launch extra with much less. Counting on traditional eventualities—guide processes and human decision-making—doesn’t reduce it anymore.

AI really has all of the powers to assist crops and factories rearrange just about each a part of their operations. For instance, industrial corporations utilizing AI can recover from all important issues, resembling extreme waste, human errors, and irrational useful resource distribution.

What Synthetic Intelligence Can Do in Manufacturing

Hack #1: Predictive Maintenance

Unplanned downtime is among the most irritating factors for any producer, and it all the time appears to occur on the worst occasions.

Because of AI, nevertheless, it has turn into doable to repair the machine earlier than it even turns into a difficulty, which is known as predictive upkeep.

By utilizing particular sensors to diagnose machines and inspecting incoming knowledge, AI can predict when a machine is about to interrupt down and plan upkeep precisely when it’s wanted.

Such an strategy visibly cuts down on dear downtime, retains the gear operating longer, and helps keep away from sudden accidents.

Hack #2: Sensible Automation

Automation isn’t new, however AI remakes it with what we name “sensible” automation.

AI can regulate extra than simply easy, duplicative duties—it memorizes and adapts, making it excellent for operating meeting traces or administering stock.

The magnificence of AI-driven automation is that it’s extra adjustable and rational. It lets folks dedicate their time to extra high-quality and refined duties whereas computer systems take over the boring, detail-intensive sides.

Hack #3: High quality Management & Defect Detection

Almost 60% of people surveyed say high quality management is the highest purpose to make use of synthetic intelligence.

With AI-powered imaginative and prescient techniques, you may spot flaws and imperfections that human eyes would possibly miss.

Put merely, AI techniques scan 1000’s of merchandise in a cut up second and catch even probably the most undersized points, serving to product high quality keep persistently excessive.

Hack #4: Provide Chain Optimization

Although AI can now be used within the end-to-end provide chain throughout the board, some years in the past, supply chain optimization by means of rising tech appeared nonsense accompanied by a number of dangers and limitations.

At present, AI is ready to rank and manage info based mostly on particular filters, shortly interpret and alter processes and operations, recap massive units of knowledge, drag crucial insights and coincidences, recognize images, and assist recuperate related data.

Hack #5: Manufacturing Planning & Scheduling

In relation to manufacturing planning, AI is nice at fine-tuning schedules to chop down on downtime and get probably the most out of each manufacturing run.

It takes real-time knowledge from all machines concerned in manufacturing, workforce availability, and shifts in demand, adjusting manufacturing plans on the fly.

In brief, this all-around strategy means higher useful resource estimates, sooner lead occasions, and smarter useful resource use. With AI, your manufacturing line runs like a well-oiled machine, all the time acting at its greatest!

Hack #6: Cobots

Cobots, or collaborative robots, are designed to work proper alongside a human group.

Not like accustomed robots that have to be separated, cobots powered by AI can adapt to help employees with their chores, whether or not it’s lifting heavy components or dealing with delicate meeting work.

They’re a fantastic AI hack for producers who wish to mix the strengths of people and the intelligence of robots.

Hack #7: Constructing One thing New

Synthetic intelligence isn’t nearly sharpening up what you already do—it’s additionally a way for experimenting and constructing solely new or beforehand unexplored merchandise or processes.

For instance, producers can use predictive modeling to identify traits and guess what prospects would possibly need, use fast prototyping to whip up and take a look at new designs very quickly, provide you with new product concepts, and make use of simulations to see how these merchandise will maintain up in numerous conditions.

The right way to Get Began with AI in Manufacturing

Embedding AI would possibly really feel a bit intimidating at first sight, however taking it step-by-step could make the transition a lot easier.

Start by pinpointing all of the areas in your workflow the place AI may make a notable impact.

For instance, consider using AI for predictive upkeep to maintain your machines operating correctly or bettering high quality management to catch the tiniest defects.

When you’ve specified these areas, you may add AI options. As you begin to see constructive results, you may steadily broaden your use of AI throughout different features of your manufacturing processes.

This tactic not solely enables you to govern the change, but it surely additionally provides your crew an opportunity to adapt to new reforms with out feeling confused.

In case you want additional assist, you may all the time staff up with an skilled AI vendor or marketing consultant. They’ll provide help to steer the combination process and show synthetic intelligence meshes properly along with your present techniques and workflows.

In the event you’re looking out for premier AI options, SCAND has obtained your again. Our staff can present you the way to use AI for corporates and create customized purposes that can open up hidden alternatives you may not even pay attention to.

The submit Top AI Hacks That Will Transform Your Manufacturing Business appeared first on SCAND.