Invisibility cloaks are often spotlighted in science fiction, showcasing futuristic expertise. Whereas comparable developments in smart clothing aren’t dominated out within the close to future, there are equally intriguing functions on the horizon. In addition to aesthetic options like color-shifting, researchers are advancing a brand new wave of good textiles able to adapting their construction to control physique temperature. A latest growth comes from a workforce of specialists at MIT in america, unveiling a cloth with this exceptional functionality.

Good textiles that change in keeping with environmental situations

Many people have doubtless skilled the dilemma of sporting too many or too few garments when stepping out on the road. Maybe the climate unexpectedly turned too sizzling, rendering a thick sweater uncomfortable. Conversely, a sudden chilly wind might have left us regretting the selection of a denim jacket as a substitute of a hotter wool coat. MIT suggests an answer to those weather-related challenges is utilizing liquid crystal elastomer (LCE) fibers, generally known as FibeRobo. These fibers can regulate physique temperature, providing a promising answer to handle such climate fluctuations.

What are their traits?

Good textiles’ distinguishing function is their capacity to sense the atmosphere and reply to stimuli, sometimes achieved by means of passive means or by using exterior vitality sources.

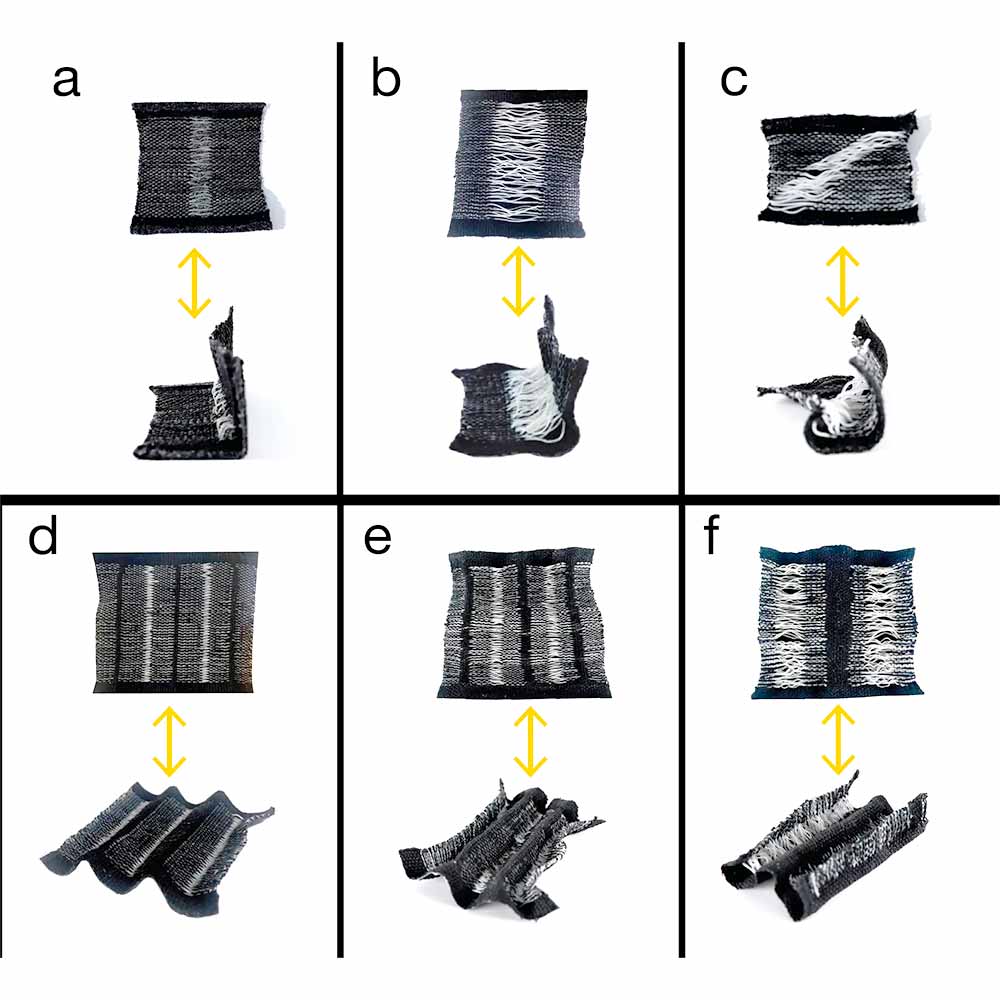

MIT’s fibers fall into the class of passive good textiles. They autonomously contract in response to a drop in temperature, enhancing thermal insulation. Because the ambient temperature will increase, the material regains its unique construction—all achieved with out electrical energy.

An extra benefit of this good cloth is its compatibility with different textiles, together with electrically conductive fibers. This permits for electrical indicators to contract or increase the material selectively. As an illustration, researchers envision sportswear clothes like bras whose cloth contracts earlier than a coaching session.

The important thing to this performance lies within the distinctive traits of the liquid crystal, able to flowing like a liquid or settling into periodic crystalline buildings. Builders built-in these crystals into an elastomer community, mimicking a rubber band’s stretching and contracting properties.

Within the presence of warmth, the crystals disarrange and compress the elastomer community, inflicting the material to contract. The manufacturing course of permits fine-tuning the thermal response to adapt to physique temperature and desired ranges of contraction or enlargement.

Producing this revolutionary textile materials posed challenges, however the analysis workforce efficiently manufactured the LCE-based fibers utilizing 3D printing and precision laser-cut components. The method includes heating resins, producing yarns by means of nozzles, and subjecting them to ultraviolet radiation. Remarkably, this method produces as much as one kilometer of fiber in a single day.

MIT’s good materials doesn’t require sensors, circuits, or digital gadgets to ship its superior functionalities. Moreover, researchers anticipate comparatively low manufacturing prices, and the fibers can seamlessly combine into present manufacturing techniques without having new equipment.

Foremost capabilities of good textiles

Alongside sustainability, the textile trade grapples with a big shift in the direction of good clothes. It is essential to tell apart between wearables, like patches built-in into T-shirts, and good materials—textile fibers intrinsic to the garment’s construction, manufactured akin to standard fibers like wool or cotton. Laboratories are at present specializing in 5 elementary functionalities, using both passive or lively applied sciences:

- Sensors: These allow clothes to detect adjustments in temperature, gentle, coronary heart charge, strain, or humidity, amongst different elements.

- Communication: Crucially, clothes will transmit info collected by sensors, both wirelessly or by means of circuits.

- Storage: Future clothes might retailer vitality inside its fibers to be used by built-in laptop techniques.

- Information processing: Good wearables are anticipated to own some computational sign processing functionality.

- Actuators: Sure fibers will convert vitality into vibration, sound, or adjustments in construction, like MIT’s thermal materials.

For deeper insights into transformative applied sciences like good materials and wearables, reshaping how we costume, work, and train, subscribe to our e-newsletter on the backside of this web page.

Supply:

Images: