Scientists have developed a groundbreaking method for printing metallic oxide movies at room temperature, creating clear, extremely conductive circuits that may stand up to excessive temperatures.

Researchers have demonstrated a method for printing skinny metallic oxide movies at room temperature, and have used the method to create clear, versatile circuits which can be each strong and capable of perform at excessive temperatures.

“Creating metallic oxides which can be helpful for electronics has historically required making use of specialised gear that’s gradual, costly, and operates at excessive temperatures,” says Michael Dickey, co-corresponding creator of a paper on the work and the Camille and Henry Dreyfus Professor of Chemical and Biomolecular Engineering at North Carolina State College. “We needed to develop a method to create and deposit metallic oxide skinny movies at room temperature, primarily printing metallic oxide circuits.”

The Significance of Steel Oxides in Electronics

Steel oxides are an vital materials present in practically each digital gadget. Most metallic oxides are electrically insulating (like glass). However some metallic oxides are each conductive and clear, and people oxides are critically vital for the contact display screen in your smartphone or the monitor in your pc.

“In precept, metallic oxide movies needs to be simple to make,” Dickey says. “In any case, they type naturally on the floor of practically each metallic object in our houses – soda cans, stainless-steel pots, and forks. Though these oxides are all over the place, they’re of restricted use since they’ll’t be faraway from the metals they type on.”

For this work, the researchers developed a novel technique to separate metallic oxide from a meniscus of liquid metallic. If you happen to fill a tube with liquid, a meniscus is the curved floor of the liquid that extends past the tip of the tube. It’s curved due to the floor rigidity that forestalls the liquid from spilling out utterly. Within the case of liquid metals, the floor of the meniscus is roofed with a skinny metallic oxide pores and skin that varieties the place the liquid metallic meets the air.

How the Liquid Steel Printing Course of Works

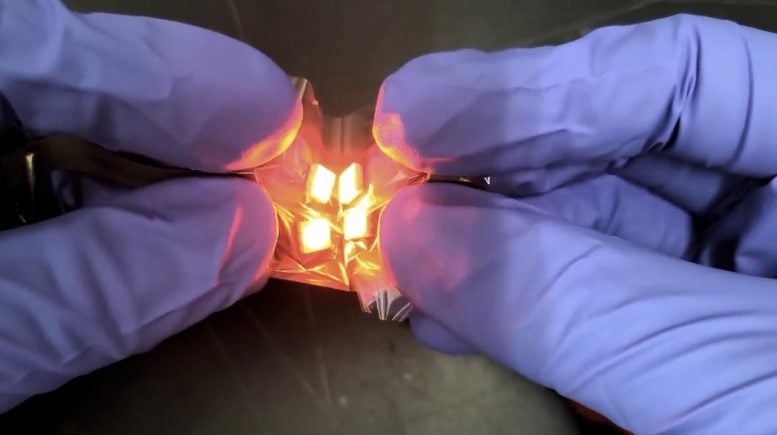

“We fill the area between two glass slides with liquid metallic so {that a} small meniscus extends past the ends of the slides,” Dickey says. “Consider the slides because the printer, and the liquid metallic is the ink. The meniscus of liquid metallic can then be introduced into contact with a floor. The meniscus is roofed with oxide on all sides, analogous to the skinny rubber that encases a water balloon. Once we transfer the meniscus throughout the floor, the metallic oxide on the back and front of the meniscus sticks to the floor and peels off, just like the path left behind by a snail. As this occurs, the uncovered liquid on the meniscus continually varieties contemporary oxide to allow steady printing.”

The result’s that the printer lays down a two-layer skinny movie of metallic oxide that’s roughly 4 nm thick.

“It’s vital to notice that regardless that we use a liquid, the metallic oxide movie deposited on the substrate is strong and extremely skinny,” Dickey says. “The movie adheres to the substrate – it’s not one thing you could possibly smudge or smear. That’s vital for printing circuits.”

The researchers demonstrated this system with a number of liquid metals and metallic alloys, with every metallic altering the composition of the metallic oxide movie. The researchers had been additionally capable of lay down a stack of layered skinny movies by making a number of passes with the printer. Watch a video of the method:

Shocking Properties of the Clear Movies

“One of many issues we discovered stunning was that the printed movies are clear however have metallic properties,” Dickey says. “They’re extremely conductive.”

“As a result of the movies have a metallic character, gold bonds to the printed oxide, which is uncommon – gold usually doesn’t keep on with oxides,” says Unyong Jeong, co-corresponding creator of a paper on the work and a professor of supplies science and engineering at Pohang College of Science and Know-how (POSTECH). “If you introduce a small quantity of gold to those skinny movies, the gold is actually integrated into the movie. This helps stop the conductive properties of the oxide from degrading over time.”

“We predict these movies are so conductive as a result of the middle of the two-layer skinny movie accommodates little or no oxygen, it’s extra metallic and fewer of an oxide,” Jeong says. “With out the presence of gold, extra oxygen makes its technique to the middle of the layered skinny movie over time, which causes the movie to grow to be electrically insulating. Including gold to the skinny movie helps stop the central a part of the movie from oxidizing. The truth that this works so effectively is stunning as a result of we’re utilizing so little gold – the oxide skinny movie continues to be extremely clear.”

As well as, the researchers discovered that the skinny movies retained their conductive properties at excessive temperatures. If the skinny movie is 4 nanometers thick, it retains its conductive properties as much as nearly 600 levels Celsius. If the skinny movie is 12 nanometers thick, it retains its conductive properties as much as at the least 800 levels Celsius.

Potential Functions and Future Collaborations

The researchers additionally demonstrated the utility of their method by printing metallic oxides onto a polymer, creating extremely versatile circuits that had been strong sufficient to retain their integrity even after being folded 40,000 instances.

“The movies may also be transferred to different surfaces, equivalent to leaves, to create electronics in unconventional locations,” Dickey says. “We’re preserving the mental property on this system and are open to working with business companions to discover potential functions.”

The paper, “Ambient Printing of Native Oxides for Ultrathin Clear Versatile Circuit Boards,” will probably be printed August 15 within the journal Science. Co-first authors of the paper are Minsik Kong, a former visiting scholar at NC State and Ph.D. scholar at POSTECH; and Man Hou Vong, a Ph.D. scholar at NC State. The paper was co-authored by Omar Awartani, a former postdoctoral researcher at NC State; Mingyu Kwak, Ighyun Lim and Younghyun Lee of POSTECH; Seong-hun Lee, Jimin Kwon and Tae Joo Shin of Ulsan Nationwide Institute of Science and Know-how; and Insang You of the College of Waterloo.

This work was finished with assist from the Nationwide Analysis Basis of Korea, funded by the Ministry of Science, beneath grants 2022M3C1A3081359 and RS-2024-00338686.