- At this time’s quickly evolving panorama of use instances that demand extremely performant and environment friendly community infrastructure is inserting new emphasis on how in-line amplifiers (ILAs) are designed and deployed.

- Meta’s ILA Evo effort seeks to reimagine how an ILA website could possibly be deployed to enhance pace and value whereas making a step operate enchancment in energy effectivity.

Over the previous yr, Meta has been on a journey to reimagine fiber optic in-line amplifier (ILA) websites. An necessary piece of community infrastructure, ILAs serve to amplify optical indicators and are sometimes positioned in distant places between knowledge facilities. If one ILA fails, a complete intercity route fails, and if one ILA can’t develop, the whole fiber route is constrained. Meta is worked up to introduce new concepts and ideas to assist modernize the ILAs for tomorrow.

To that finish, we’ve launched the ILA Evo effort to beat the historic design constraints of as we speak’s ILAs, particularly:

- The minimal expert labor and uncooked materials required on the deployment website;

- The requirement that buildings meet native snow, wind, and seismic load together with fireplace codes and well being and security regulation – plus lifespan better than 25 years;

This new effort seeks to propel development by way of a number of new necessities:

- Requiring the constructing and inside plant (ISP) should be deployed in three to 4 days.

- Decreasing the necessity for specialised heavy tools (avoiding the price and time for heavy-lift cranes to journey to a distant website).

- Minimizing concrete (keep away from value and time to move, kind, tie rebar, pour, and remedy concrete).

- Decreasing the ability utilization effectiveness (PUE) to lower than 1.5 – nowhere close to Meta’s operational data center PUE average of 1.09 (2023 common), however an achievable and important enchancment.

A brief historical past of ILAs

Fiber optic cable networks have seen exponential progress in each measurement and capability since GTE launched the first fiber optic network in 1977. U.S. network operators would install 20,039 mi (32,250 km) of intercity fiber routes by 1985. This might quadruple to 83,618 mi (134,570 km) by 1989 and double again to 159,779 mi (257,149 km) by 1998, with MCI, Dash, USTelecom, and WilTel being the most important gamers in these early days.

As fiber was rolled out alongside roads, railways, and pipelines, actual property to accommodate optical sign repeaters was developed in parallel. What later grew to become identified ILA websites have been spaced 18 to 25 miles (30 to 40 km) aside. With fast enhancements in each optical fiber purity and composition, plus developments in optronics, spacing quickly doubled into the 50 to 60 mile (80 to 100 km) vary the place it has largely remained till as we speak.

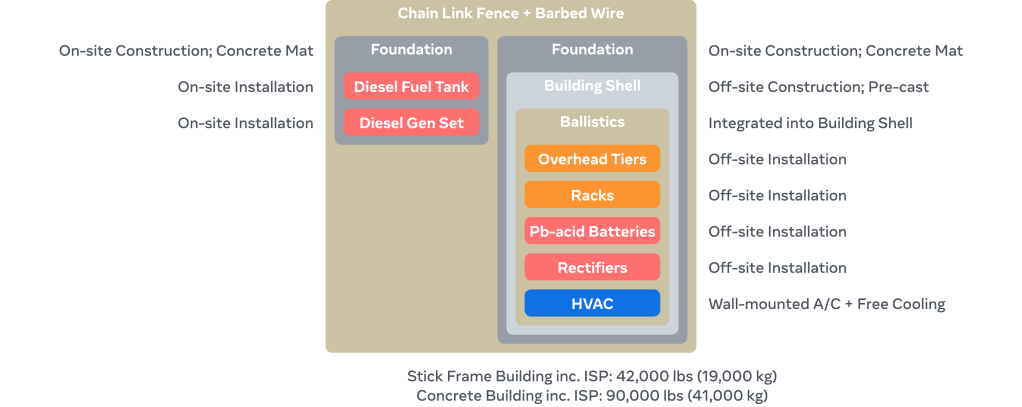

Early ILA constructing designs have been roughly modeled on Bell Phone central workplaces, albeit a shrunken down model: concrete shells (or stick framed building on a metal I-beam base) positioned atop concrete foundations; wall-mounted HVAC items; -48V energy distribution; lead-acid batteries; diesel backup turbines and so forth surrounded by chain hyperlink fences.

Buildings have been constructed in a central location with ISP fitted into the shell earlier than cargo to the location (by way of specialised motor service) and positioned with a heavy-load crane. Nevertheless, in contrast to the outstanding (and ongoing) developments in fiber and optronics (e.g., CWDM to DWDM to Coherent DWDM), ILA websites themselves have obtained little consideration.

At this time’s ILA buildings are sometimes bigger, with extra environment friendly HVAC programs. Parts like safety and constructing entry programs have been modernized, however should you dropped a subject technician from 1990 into one among as we speak’s ILAs, they’d have little problem navigating. Traditionally, ILA websites haven’t required important evolution, nonetheless newfound capability progress and innovation has warranted the event of recent ILA approaches.

The construction of ILA Evo

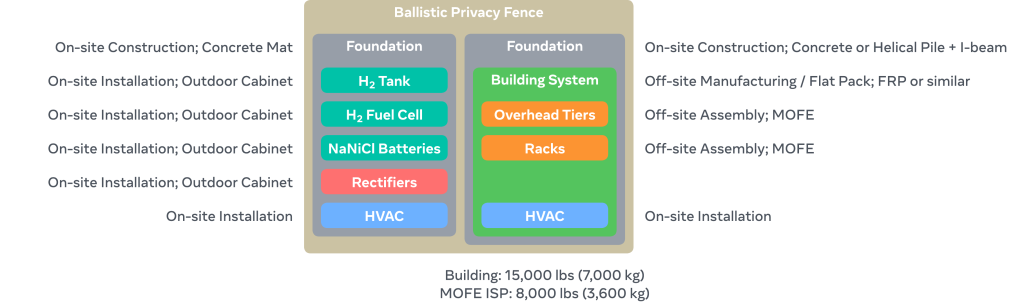

Working with world engineering consultancy AECOM, we’ve organized the issue and our engineering efforts into a number of classes: completely different constructing programs and foundations; a brand new ISP set up technique; different ballistics safety; introducing extra environment friendly cooling; and modernizing backup energy programs.

Constructing system

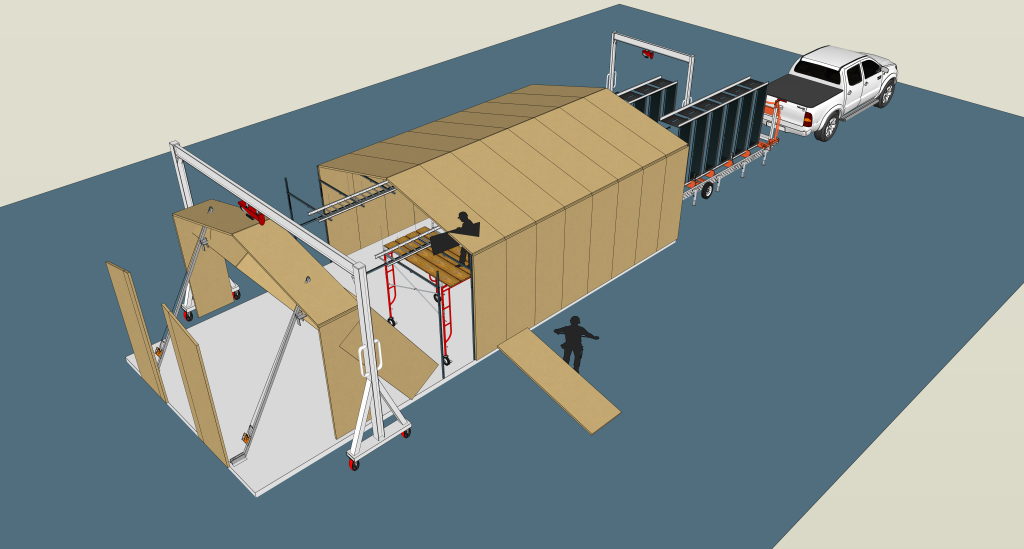

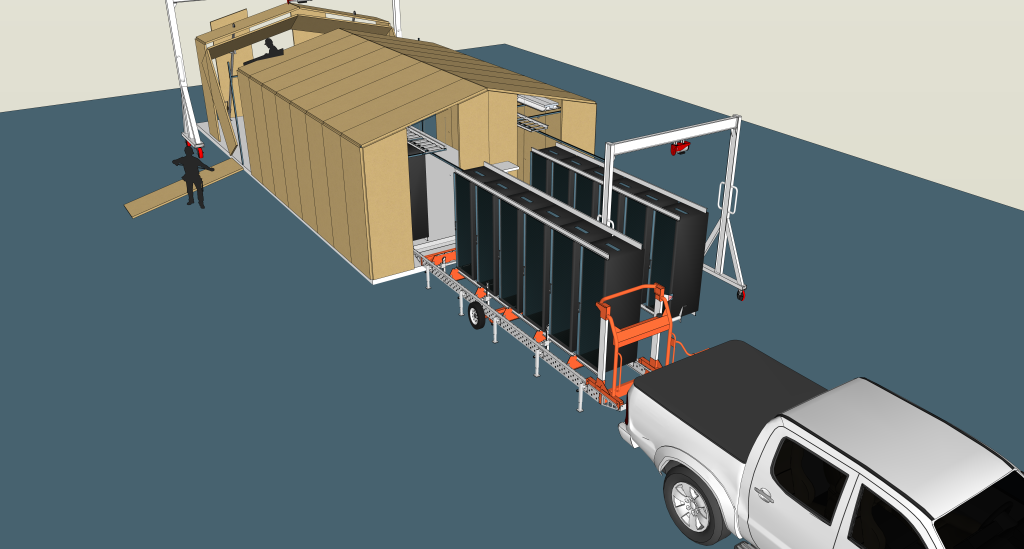

Establish light-weight constructing designs which might be flat packed for straightforward, fast cargo and unloaded on the deployment website utilizing a raise gate. Our emphasis has been on buildings composed of fiberglass-reinforced polymer (FRP) aka glass-reinforced polymer (GRP) wall and roof panels gentle sufficient for 2 individuals to deal with, however sturdy sufficient to satisfy our design wants. There’s a sturdy ecosystem of firms providing options on this house. This method additionally permits for barely taller buildings than prefab to supply further overhead house for HVAC system parts or different elements.

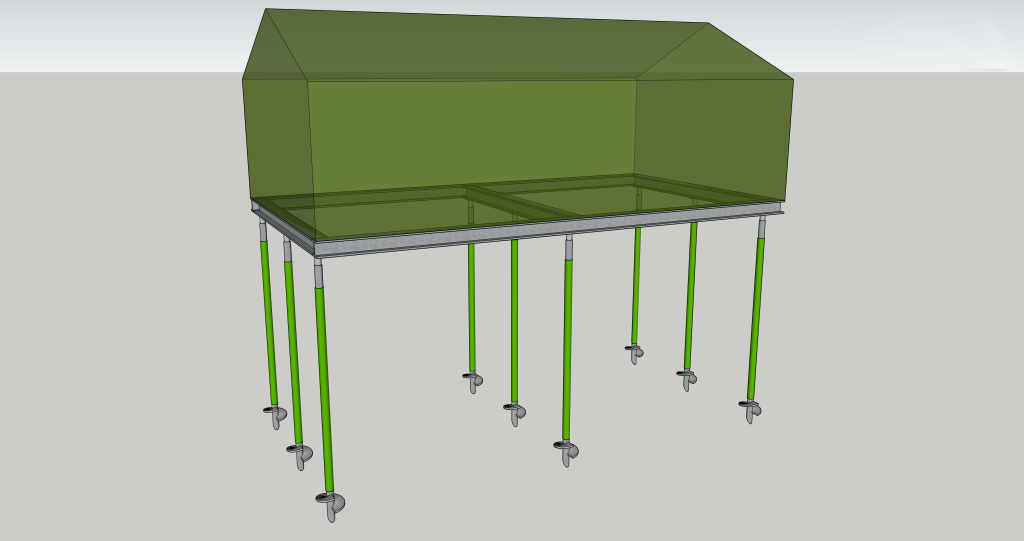

Constructing foundations

The place geology permits, make the most of low- or no-concrete basis designs for simpler deployment into each greenfield and brownfield websites. Usually, ILA buildings sit atop slab-on-grade foundations with a fringe edge return. This design works effectively in a wide range of soil circumstances and is effectively suited to the weights concerned. Nevertheless, as we pursue lighter buildings, different basis designs turn out to be doable. Specifically, the undertaking has targeted on metal or FRP I-beams over concrete pad footings or helical metal screw piles. Each choices supply the potential for each decrease value and extra fast deployment.

Manufactured owner-furnished tools ISP

Devise a course of for quickly putting in ISP to attenuate post-construction inside mud and particles clean-up. We envision using a manufactured owner-furnished tools (MOFE) course of for ISP: six rack modules consisting of apparatus racks and overhead tiers supported by an exoskeleton, and movable on casters, are preassembled in a centralized, clear factory-like setting. Just like the constructing system, these might be delivered on common vans with raise gates and modules rolled into the constructing to be bolted down.

Ballistics

The place required, present applicable ballistics safety; e.g., NIJ 0101.06 Degree IIA. Nevertheless, we felt assigning this operate to the constructing system wasn’t the one choice, so we’ve left open the potential of ballistic privateness fences and different concepts as methods to unravel this requirement which gives extra flexibility for what “contained in the fence” might appear to be.

Cooling

The one largest alternative to enhance PUE lies in introducing extra environment friendly cooling tech mixed with larger temperature set factors. PUE hasn’t traditionally been a spotlight metric for small telecoms websites, however this wants to alter. Conventional websites use self-contained, wall-mounted HVAC items that depend on giant followers to pressure air by way of the constructing and not using a duct system. This method works, however shouldn’t be very environment friendly: North American ILA PUE is usually between 2.5 and three.0. Nevertheless, over the previous few years, energy necessities have moved from 600-800W per rack into the 2-4 kW vary. With growing energy density, we started in search of different choices which might do the job extra successfully and effectively (i.e., scale back PUE).

Major parts:

- Radically enhance ILA website HVAC effectivity with superior passive (i.e., compressorless) and/or liquid-based cooling tech.

- As a result of ILAs are unmanned, permit the constructing to run hotter: e.g., enhance temperature set factors from typical 22°C (72°F) to >35°C (95°F); most optical transport equipment is GR-63-CORE NEBS-3 compliant and capable of run repeatedly at 40°C (104°F).

- Thermally “leaky” constructing programs; i.e., not air leaks , however decrease R-value partitions.

- Transfer rectifiers and batteries into out of doors cupboards: extra space for optical gear and fewer warmth era.

- Make the most of cool surface materials and coatings (e.g., warmth reflective paints) to additional scale back photo voltaic warmth load.

The undertaking investigated many hyper environment friendly choices corresponding to chilled beams (ceiling mounted, air-to-liquid warmth exchangers) mixed with a ground-based warmth trade (water or glycol circulating in a closed, buried floor loop), however sadly, none might deal with 24 x 2 kW. Nevertheless, a loop thermosyphon system coupled with a high-efficiency compressor (a helper used through the hottest a part of the most well liked days) might obtain our PUE <1.5 aim. Equally, scaled-down chiller and laptop room air con (CRAC) items supplying liquid cooling right into a thoughtfully designed ground plan might get us to that very same aim.

The undertaking hasn’t made a remaining choice but as these applied sciences will make our aim of “no cranes” tough to realize, however we imagine we’ve got line-of-sight to an answer.

Backup Energy

Examine fashionable alternate options to diesel turbines and lead-acid batteries for standby energy. We’re contemplating substitutions for diesel generator backup which will embody H2 gasoline cells, capacitors, or different options primarily based on location and business feasibility.

Moreover, we’ve got investigated a spread of battery applied sciences. For the time being, the economics aren’t enticing for this scale. Within the meantime, we imagine an H2 gasoline cell mixed with a small NaNiCl molten salt battery system (to deal with website load for a couple of minutes whereas the gasoline cell spins up and takes load) is a pretty, low upkeep answer.

Macro advantages of ILA Evo

Past the technical elements, ILA Evo brings doubtlessly highly effective business and danger administration advantages: provide chain and skill to stockpile.

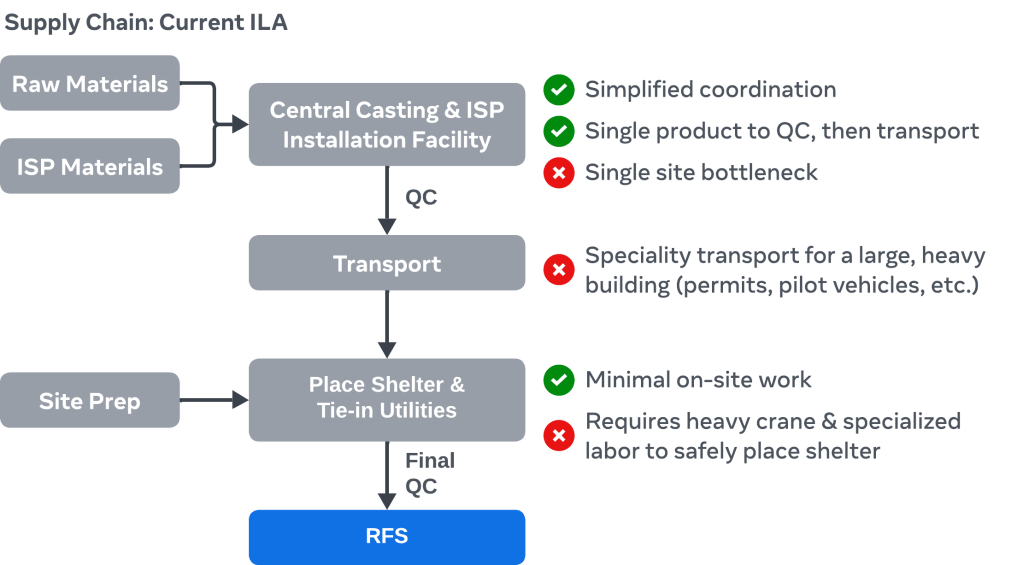

Beginning with the acquainted present ILA provide chain, the chief benefit is finishing the vast majority of work at a single website. Nevertheless, this creates challenges when it comes to value, the complexity of scaling manufacturing up or down, and the problem and value of transporting the required heavy tools to distant websites. Moreover, the feasibility of stockpiling present ILA buildings is debatable: The house requirement would eat worthwhile actual property on the manufacturing website and staging them off-site merely amplifies the transportation problem to maneuver them a number of instances.

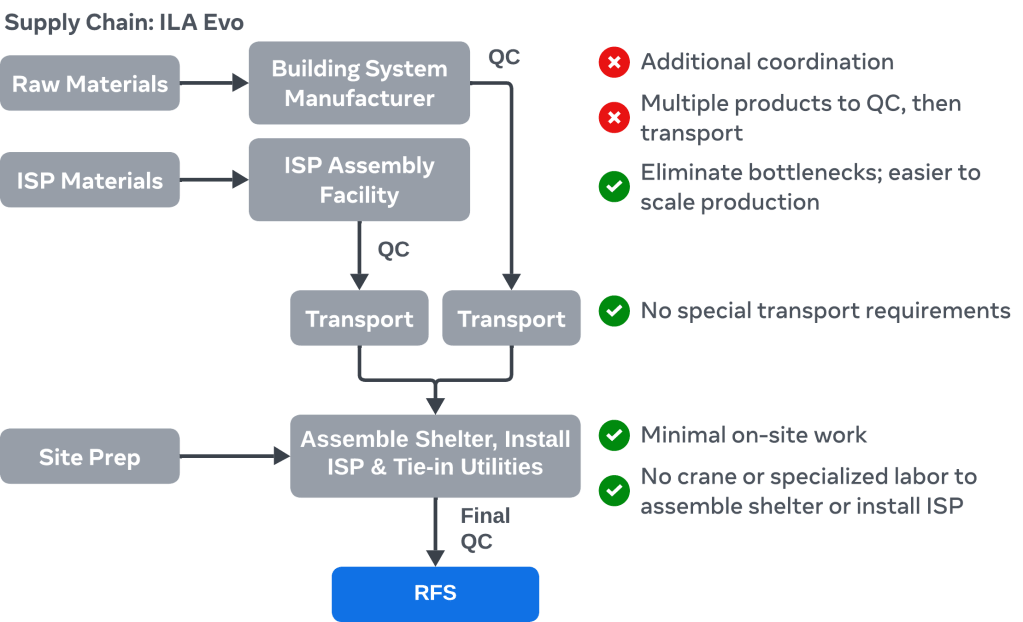

Seeking to ILA Evo and beginning with a brand new disaggregated provide chain, many ISP supplies and different gadgets like HVAC items would most probably come from the standard sources, however these sources already are usually scaled. Different parts such because the constructing system and MOFE ISP can be manufactured or assembled by firms that aren’t essentially a part of as we speak’s telecom ecosystem.

Moreover, the method may be very completely different. Concrete and stick framed buildings are created by way of a building course of, the character of which is bespoke and comparatively low quantity. ILA Evo is predominantly manufacturing or meeting processes, that are inherently geared towards scale, together with the potential of 24×7 operations.

Subsequent, stockpiling. It’s not onerous to think about manufacturing 500 constructing programs, packed effectively and prepared for subsequent day cargo. One may also think about 2,000 MOFE ISP modules (4 for every 24 rack constructing) preassembled and able to ship. Moreover, buying in bulk permits distributors to de-risk their very own investments and obtain scales required for value compression not doable with as we speak’s designs.

Crossover with present ILA design

One remaining consideration is figuring out concepts that could possibly be retrofitted into current websites. Placing apart a distinct constructing system and MOFE ISP, the HVAC system and the opposite “effectivity tweaks” might go into current websites. Equally, H2 gasoline cell backup energy could possibly be utilized. We additionally anticipate to discover substituting commodity ISP supplies for his or her FRP analogs. If this works, FRP tools racks and ladder racks (which have a decrease carbon footprint than metal or aluminum) may be an choice for current websites.

What’s subsequent?

Following the completion of our analysis and design part, there are a variety of subsequent steps deliberate for 2025:

- The undertaking has already engaged fiber optic operators in North America and Europe to collect early suggestions and acquire their insights. Within the coming months, we anticipate to broaden this session with operators in Latin America, Africa, Center East, and Asia.

- A prototype website showcasing among the greatest concepts from this work.

- We plan to create and broadly share blueprints, payments of fabric, and analyses that present our path and assist seed operators’ personal analysis, engineering, and technical actual property product growth.