A cheap course of with inexperienced hydrogen can be utilized to extract CO2-free iron from the crimson mud generated in aluminium manufacturing

The manufacturing of aluminium generates round 180 million tonnes of poisonous crimson mud yearly. Scientists on the Max-Planck-Institut für Eisenforschung, a centre for iron analysis, have now proven how inexperienced metal might be produced from aluminium manufacturing waste in a comparatively easy means. In an electrical arc furnace much like these used within the metal business for many years, they convert the iron oxide contained within the crimson mud into iron utilizing hydrogen plasma. With this course of, virtually 700 million tonnes of CO2-free metal could possibly be produced from the 4 billion tonnes of crimson mud which have collected worldwide to this point – which corresponds to a very good third of annual metal manufacturing worldwide. And because the Max Planck crew reveals, the method would even be economically viable.

In keeping with forecasts, demand for metal and aluminium will enhance by as much as 60 % by 2050. But the traditional manufacturing of those metals has a substantial impression on the setting. Eight % of worldwide CO2 emissions come from the metal business, making it the sector with the best greenhouse gasoline emissions. In the meantime, the aluminium business produces round 180 million tonnes of crimson mud yearly, which is extremely alkaline and accommodates traces of heavy metals resembling chromium. In Australia, Brazil and China, amongst others, this waste is at greatest dried and disposed of in gigantic landfill websites, leading to excessive processing prices. When it rains closely, the crimson mud is commonly washed out of the landfill, and when it dries, the wind can blow it into the setting as mud. As well as, the extremely alkaline crimson mud corrodes the concrete partitions of the landfills, leading to crimson mud leaks which have already triggered environmental disasters on a number of events, for instance in China in 2012 and in Hungary in 2010. As well as, giant portions of crimson mud are additionally merely disposed of in nature.

Potential to avoid wasting 1.5 billion tonnes of CO2 within the metal business

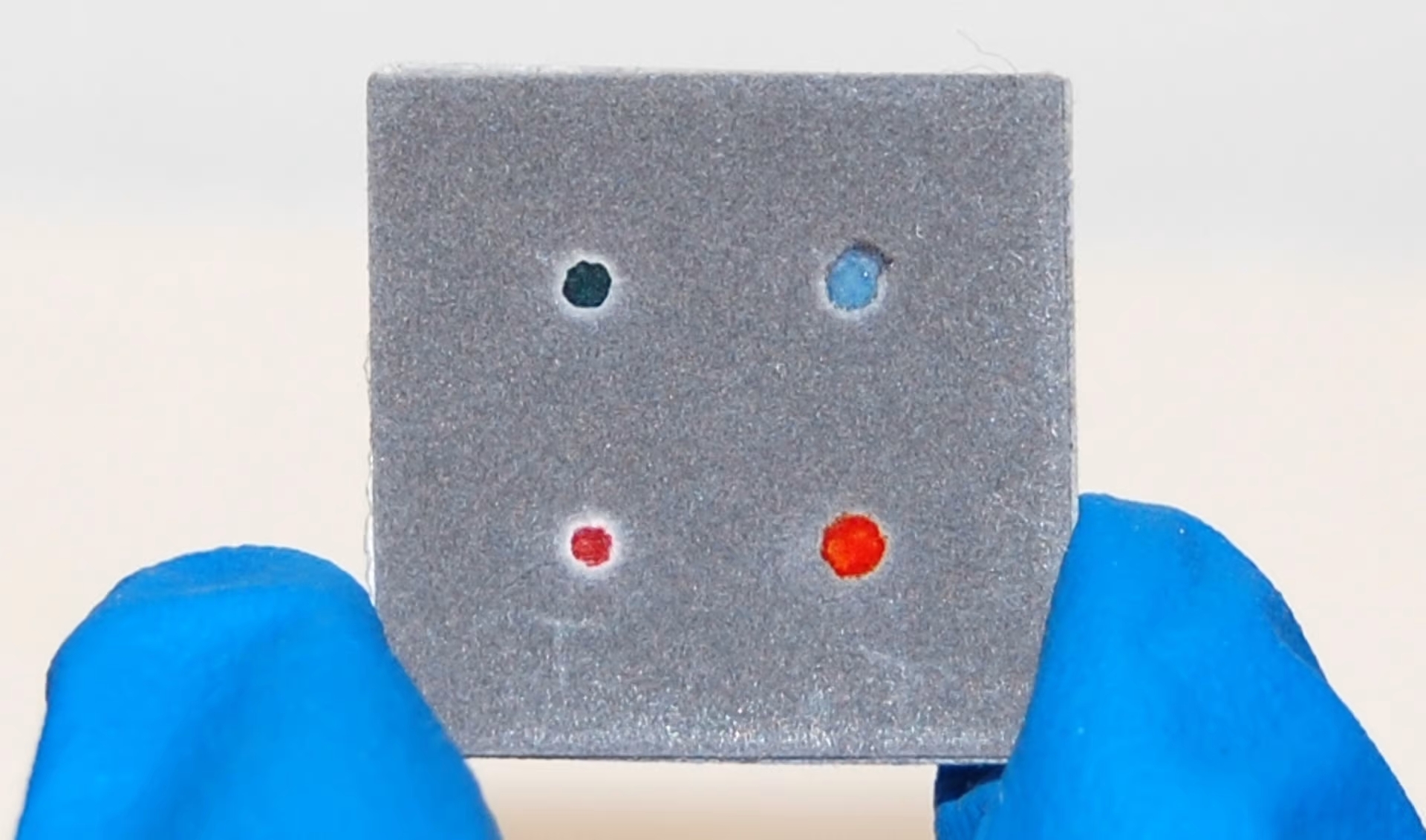

“Our course of might concurrently remedy the waste drawback of aluminium manufacturing and enhance the metal business’s carbon footprint,” says Matic Jovi?evi?-Klug, who performed a key function within the work as a scientist on the Max-Planck-Institut für Eisenforschung. In a research printed within the journal Nature, the crew reveals how crimson mud might be utilized as a uncooked materials within the metal business. It’s because the waste from aluminium manufacturing consists of as much as 60 % iron oxide. The Max Planck scientists soften the crimson mud in an electrical arc furnace and concurrently cut back the contained iron oxide to iron utilizing a plasma that accommodates ten % hydrogen. The transformation, recognized in technical jargon as plasma discount, takes simply ten minutes, throughout which the liquid iron separates from the liquid oxides and may then be extracted simply. The iron is so pure that it may be processed straight into metal.

The remaining metallic oxides are not corrosive and solidify on cooling to kind a glass-like materials that can be utilized as a filling materials within the building business, for instance. Different analysis teams have produced iron from crimson mud utilizing an analogous strategy with coke, however this produces extremely contaminated iron and huge portions of CO2. Utilizing inexperienced hydrogen as a lowering agent avoids these greenhouse gasoline emissions. “If inexperienced hydrogen could be used to provide iron from the 4 billion tonnes of crimson mud which have been generated in international aluminium manufacturing to this point, the metal business might save virtually 1.5 billion tonnes of CO2,” says Isnaldi Souza Filho, Analysis Group Chief on the Max-Planck-Institut für Eisenforschung.

A cheap course of, together with with inexperienced hydrogen and electrical energy

The heavy metals within the crimson mud will also be nearly neutralized utilizing the method. “After discount, we detected chromium within the iron,” says Matic Jovi?evi?-Klug. “Different heavy and treasured metals are additionally seemingly to enter the iron or right into a separate space. That’s one thing we’ll examine in additional research. Helpful metals might then be separated and reused.” And heavy metals that stay within the metallic oxides are firmly sure inside them and may not be washed out with water, as can occur with crimson mud.

Nonetheless, producing iron from crimson mud straight utilizing hydrogen not solely advantages the setting twice over; it pays off economically too, because the analysis crew demonstrated in a value evaluation. With hydrogen and an electrical energy combine for the electrical arc furnace from solely partially renewable sources, the method is worth it, if the crimson mud accommodates 50 % iron oxide or extra. If the prices for the disposal of the crimson mud are additionally thought of, solely 35 % iron oxide is adequate to make the method economical. With inexperienced hydrogen and electrical energy, at immediately’s prices – additionally bearing in mind the price of landfilling the crimson mud – a proportion of 30 to 40 % iron oxide is required for the ensuing iron to be aggressive in the marketplace. “These are conservative estimates as a result of the prices for the disposal of the crimson mud are most likely calculated moderately low,” says Isnaldi Souza Filho. And there’s one other benefit from a sensible viewpoint: electrical arc furnaces are broadly used within the metallic business – together with in aluminium smelters – as they’re used to soften down scrap metallic. In lots of instances, the business would due to this fact want to take a position solely somewhat to turn out to be extra sustainable. “It was essential for us to additionally think about financial facets in our research,” says Dierk Raabe, Director on the Max-Planck-Institut für Eisenforschung. “Now it’s as much as the business to resolve whether or not it’ll make the most of the plasma discount of crimson mud to iron.”

Authentic Article: Green steel from toxic red mud

Extra from: Max Planck Society