On this web page, we’ve spoken on a number of events concerning the potential of 5G, which is rapidly turning into a typical in developed nations. The advantages are simple, from the decreased latency that may assist driverless automobiles to the protection of tens of millions of units per sq. mile driving the Web of Issues. Nevertheless, not everybody advantages on the similar charge. Getting the most deprived and distant areas to take part in these advances is the objective of a venture on the College of Sheffield in the UK.

What are the principle 5G infrastructures and bands?

The deployment of 5G networks requires substantial investments in radio spectrum and {hardware} within the type of antennas. A lot in order that implementation is gradual, with two kinds of structure:

- Non-Stand Alone Structure (NSA), which takes benefit of the prevailing 4G infrastructure, though with restricted functionalities. Thus, they’ve a latency of 15 ms and speeds of as much as 2 Gbps.

- Stand Alone (SA) structure, which can allow the total potential of 5G to be realized, together with latencies of 1 ms and transmission speeds of as much as 20 Gbps.

Moreover the {hardware} facet of issues, 5G antennas are additionally labeled by the bands wherein they function.

- Sub-6, which function under 6 GHz, sometimes between the three.4 GHz and three.8 GHz frequencies. These are utilized in city environments, as they endure much less interference from bodily or climatic obstacles.

- mmWave or millimeter wave, which function between 24 GHz and 100 GHz. These frequencies provide increased velocity and decrease latency however require a extra important variety of repeaters to compensate for the dearth of penetration. That is the kind of frequency that shall be used as a precedence in 5G SA infrastructures.

3D Printing of 5G and 6G Antennas

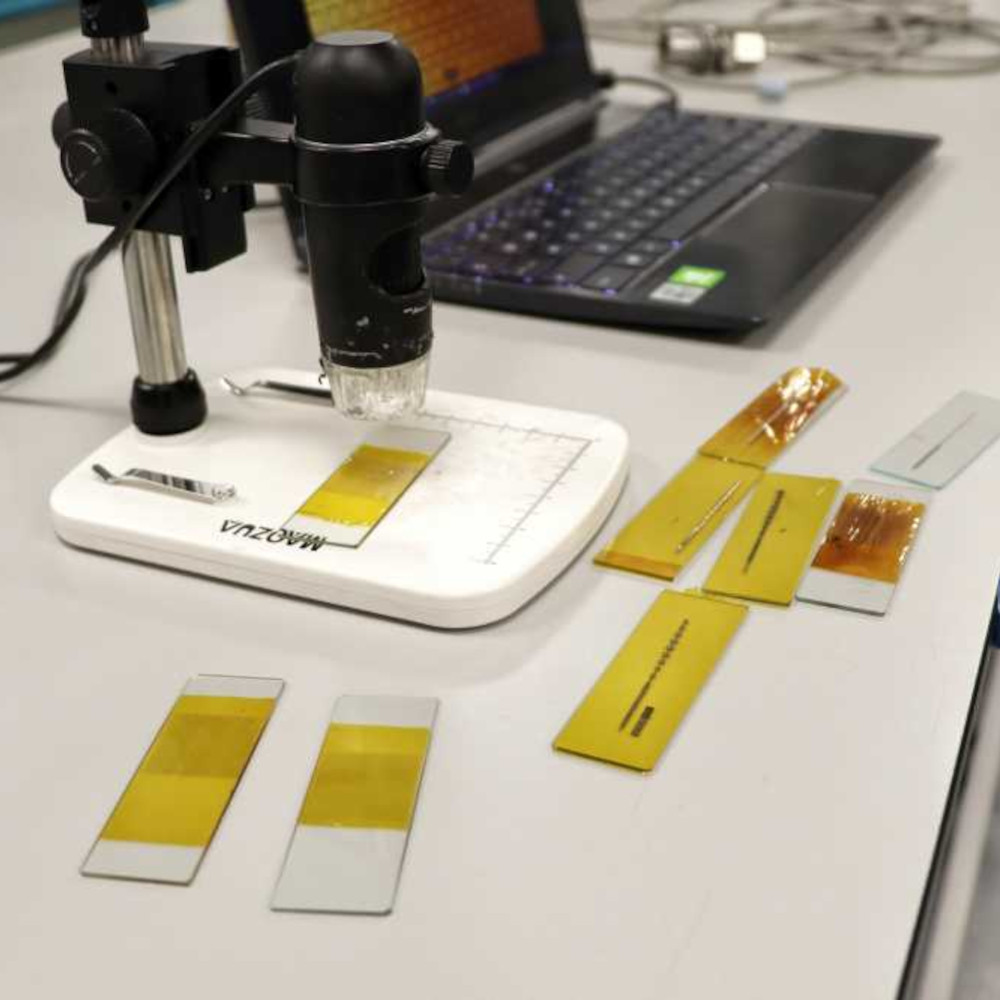

As seen, mmWave antennas shall be essential to take full benefit of this expertise. And people are the 3D-printed units developed by the Division of Digital and Electrical Engineering on the College of Sheffield. The British college has simply demonstrated the feasibility of 3D-printed 5G and 6G antennas, radically decreasing value and manufacturing instances.

Thus, the brand new method makes use of silver nanoparticles to print antennas in a couple of hours at the price of only a few {dollars}, all with out sacrificing performance. As compared, conventional 5G mmWave antennas can value a whole bunch of euros, with a lot slower manufacturing.

The builders level out that the brand new design will make it potential to provide large-scale, low-cost antennas to achieve distant areas and supply protection rapidly and effectively. Standards comparable to miniaturization, velocity of manufacture, low value, and ease of set up outline the usefulness of such a expertise in growing nations.

Initiatives like this solar desalination plant developed by MIT convey expertise, power, and water to underprivileged areas. That is additionally the raison d’être of the Acciona Foundation, which carries out initiatives to take water or clean energy to unreached areas, comparable to Oaxaca or the tropical forests of Peru. Undoubtedly, power expertise and infrastructure advances are one of many keys to growing these areas.

A brand new age of additive manufacturing electronics

We’ve got already seen that 3D printing has a variety of purposes, together with metals and biomaterials. In recent times, the scarcity of microchips attributable to issues in logistic chains attributable to the pandemic and conflict conflicts has been a continuing. And right here, 3D printing may additionally play an important function.

Additive manufacturing electronics (AME) allow 3D printing to provide semiconductors, sensors, transistors, and different laptop parts, wearables, and circuitries.

A concrete instance on this area is a venture on the College of Washington, which has created a thermoelectric gadget that converts physique warmth into electrical energy. They’ve used a 3D printing system that generates completely different layers with particular functionalities to realize this.

Thus, a liquid steel alloy filler is used that provides the wearable conductivity whereas concurrently permitting it to stretch. The gadget additionally comprises microspheres that transmit warmth to the semiconductors within the base layer. Based on the researchers, such a wearable could be printed on textiles and curved surfaces.

Additive manufacturing electronics is a way with nice potential. A lot in order that some research recommend it may quadruple in worth over this decade, reaching virtually $40 billion by 2030.

Supply: