For those who’re working a small enterprise, you’re all the time fascinated with easy methods to make your services or products pretty much as good as it may be. And also you’re placing the very best of these concepts into motion.

However are these adjustments having a tangible influence on buyer satisfaction? Are there different areas the place your assets can be higher spent?

Efficient administration isn’t nearly revenue margins. It’s additionally about prioritizing the client, who you depend upon to drive success.

That is additionally known as having a buyer focus, and it prioritizes the wants and needs of the client above another issue. It’s central to all approaches to Whole High quality Administration (or TQM for brief). Let’s take a look at easy methods to take this and different key principals, and successfully apply them throughout the context of your distinctive enterprise.

What Is Whole High quality Administration?

At all times put the client first.

The U.S. market confronted competitors from Japan within the late Nineteen Seventies and early Nineteen Eighties. Japan was in a position to produce high-quality automotive and digital merchandise at decrease costs.

Consequently, companies within the U.S. appeared extra carefully on the high quality of Japanese merchandise. Their objective was to search out methods to recapture their misplaced share of the market by way of improved merchandise. What might they study from their opponents?

The answer was TQM. All the things it’s essential know is true within the identify:

- Whole refers back to the involvement of all crew members, from product improvement to customer support. Everybody within the enterprise is targeted on the identical objective, and every division is held answerable for what it contributes to the overall Customer Experience (CX).

- High quality is the last word objective of TQM. Extra particularly, it’s about growing product or service quality, and because of this providing extra worth to clients.

- Administration encompasses everybody who oversees the method of TQM implementation, figuring out and resolving factors of friction to be able to enhance effectivity.

Because the framework, strategies, and practices turned common within the mid Nineteen Eighties, your small business would possibly already be using TQM practices with out realizing it. They’re nonetheless simply as related immediately. As a customer-focused administration type, TQM drives secure, long-term success.

5 Approaches To Whole High quality Administration for Your Small Enterprise To Take into account

TQM is a reasonably broad idea. The methods it’s utilized take varied names and varieties. However all are centered on the concept of creating your product to make sure customer loyalty and satisfaction.

The next approaches to whole high quality administration are all price investigating. Whether or not you undertake them wholesale, or adapt the elements most related to your small business mannequin, they will rework every thing from the way you deal with buyer assist interactions to how your merchandise are designed.

1. Lean Administration

Lean Administration, often known as simply “Lean”, focuses on waste discount. The objective is to focus on and eradicate pointless processes, thereby growing effectivity.

All the things you do ought to add worth for the client. Useful resource sinks and time-consuming duties that don’t create worth might be reduce out. When completed proper, this improves your profitability, and it enhances high quality by making certain that every thing you do improves buyer satisfaction.

The 5 Rules of Lean Administration

Making use of this strategy to whole high quality administration requires prioritizing five principles:

- Determine worth. Determine the issue clients want solved, and develop your services or products into the perfect answer. Any course of that doesn’t add worth to the ultimate product ought to be eliminated.

- Perform worth stream mapping. Map out key workflows, so you may see every step and the way all of them join. That is important for locating pointless parts, redundancies, and so forth.

- Create a steady workflow. Forestall any cross-functional teamwork bottlenecks. Breaking down the whole thing of a piece course of into smaller elements makes it simpler to take away roadblocks.

- Set up a pull system. Be certain that the workflow stays secure. It is a lean-specific approach that decreases the waste of manufacturing processes. For instance, new work ought to solely be began if there’s demand for it, lowering pointless overhead.

- Facilitate steady enchancment. Use varied strategies to determine what your group has completed, what it must do, and the way all crew members could make work processes simpler.

2. Six Sigma

Six Sigma is a variation on the Lean philosophy. It was developed by Motorola within the Nineteen Eighties, though Toyota was the corporate that made it most well-known. Many books have been written concerning the methodology behind Six Sigma, its variations, and Lean generally.

This specific technique may be very data-driven, to align with manufacturing rules whereas nonetheless conserving the client in thoughts. To an extent, it prioritizes effectivity within the now versus long-term considering, which is the place it barely differs from different approaches to whole high quality administration.

Six Sigma is aimed toward eliminating any defects from a course of. In the case of Toyota, through the use of Six Sigma rules it was in a position to pinpoint friction within the engine manufacturing course of. This led to a lower in faulty items, and helped to determine bottlenecks all through the availability chain.

Six Sigma’s 5-Step Strategy: DMAIC

Whereas the main points are advanced, the basic steps of Six Sigma might be summarized as follows:

- Outline. A crew, sometimes led by somebody licensed in Six Sigma, identifies a course of to give attention to and defines the issue to be solved.

- Measure. The crew measures the efficiency of the method, and creates a benchmark objective. They then create a listing of issues that is perhaps hindering efficiency.

- Analyze. The crew analyzes the method by taking a look at every enter or cause for failure/friction, and explores it by way of testing to search out the precise root trigger(s).

- Enhance. The crew implements adjustments to resolve the issue and meet the specified benchmark.

- Management. Lastly, the crew decides on ‘management parameters’ to observe, chosen to make sure that the issue doesn’t come up once more.

The “KAIZEN” philosophy is an adaptation of the Six Sigma framework, and is all about steady enchancment. Initially developed to cut back waste in manufacturing, Kaizen’s guiding star is that every thing can all the time be completed higher or improved on.

All issues ought to truly be seen as blessings, and as alternatives to develop your services or products. Kaizen has its own set of key principles, and is an equally attention-grabbing methodology.

3. ISO 9000

ISO 9000 is a set of requirements for High quality Administration Methods (QMS). These requirements act as purposeful tips for the implementation of high quality administration.

“ISO” refers back to the “Worldwide Group for Standardization” (ISO), which develops worldwide requirements for quite a few industries. It formalized the overall rules of TQM right into a set course of that firms can turn into “licensed” in.

Even with out pursuing that official certification, although, ISO 9000 gives a novel place to begin for companies seeking to maximize high quality. It gives definitive tips by which to judge inner processes for effectivity.

ISO 9000s High quality Administration Principals

The ISO 9000 household of requirements relies on seven quality management principles:

- Buyer focus. The insistence on buyer wants and necessities is a recurring pattern all through all approaches to whole high quality administration.

- Management. With out the assist of administration, no ISO (or TQM) system can perform successfully. Administration must be concerned in each choice and step.

- Engagement. Workers are a key useful resource for figuring out and resolving issues by way of communication. Group members can contribute to enhancing all processes, from improvement to customer support.

- Course of strategy. It’s important to investigate and scrutinize every particular person variable within the improvement of a product.

- Enchancment. The ISO 9000 sequence varieties a extra structural strategy to enchancment, wherein all workers are concerned. A “tradition of high quality” is fostered by way of measurement of efficiency throughout the whole group.

- Proof-based choice making. Proof-based choices ought to be made primarily based on the gathering of goal information, qualitative survey outcomes, and so on.

- Relationship administration. Companies that carefully monitor and respectfully are inclined to inner and exterior relationships nurture extra productive and constructive involvement, making a suggestions loop of engagement.

4. High quality Perform Deployment

High quality Perform Deployment (QFD) is a strategy for translating buyer wants and expectations into particular merchandise or service options. The event of our personal helpdesk software program, Groove, is a good instance of QFD in motion.

Within the preliminary levels of Groove’s improvement, we didn’t collect much customer feedback. We weren’t constructing a product primarily based on the wants of our future clients. We had been constructing it primarily based on our assumptions of what they wished.

Success got here extra readily once we put the voice of the client (VOC) first. It is a key idea of QFD, and encompasses each said and unspoken buyer wants.

The VOC can captured by way of customer satisfaction surveys, interviews, social media conversations, focus teams, commentary, and even subject reviews. Any and all direct suggestions is effective.

The objective is to make use of that suggestions to prioritize the suitable parts within the manufacturing and improvement levels. Suggestions loops are then used to refine product improvement.

4 Levels of High quality Perform Deployment

The comprehensive process of QFD is usually divided into 4 levels:

- Product planning. Take heed to the client, gather suggestions, and seize the VOC. Interpret their necessities and contemplate these as design or service options.

- Design deployment. Determine the design traits or product options that immediately correlate to buyer issues.

- Course of planning. Decide your manufacturing processes or improvement processes. Determine the particular operations – the steps for meeting or manufacturing that correlate to the specified design traits.

- Manufacturing planning. Design, construct, and implement the manufacturing or manufacturing course of specified by the third stage. Develop management necessities (what ought to be monitored throughout manufacturing), and set up upkeep necessities.

5. PDCA

PDCA stands for Plan-Do-Verify-Act, or typically Plan-Do-Verify-Regulate. It’s a four-step process that sustains steady enchancment inside a corporation or enterprise:

- Plan: Set up aims and processes.

- Do: Implement the plan.

- Verify: Assess and consider the collected and measured outcomes.

- Act: Apply acceptable adjustments primarily based on the outcomes.

PDCA is used to regulate the advance of a course of or product. It’s carefully associated to each the Six Sigma methodology and the general Lean strategy.

The objective of the PDCA cycle is to determine potential issues and current a number of options, adjusting accordingly. It’s one a part of a complete systematic course of for enchancment. As a result of it is a cycle, it doesn’t finish after the “act” step, however begins once more.

Making an attempt out PDCA inside your personal enterprise begins with three questions:

- What are you making an attempt to perform?

- How will you determine {that a} change is an enchancment?

- What adjustments are you able to make that may lead to enchancment?

Try to be clear when answering these questions, formulating particular objectives with set timelines. PDCA requires corrective actions and actionable steps to incite change.

3 Suggestions for Making use of Whole High quality Administration To Your Small Enterprise

Implementing these approaches to whole high quality administration can appear slightly daunting. We’ve solely scratched the floor right here, but it surely’s already clear how a lot work and complexity is concerned.

However you don’t need to turn into an skilled in one in every of these methodologies to realize success. There are many methods to proactively apply the core concepts of TQM with out an intensive course or fancy certification. Listed below are just a few methods to get began.

Tip #1: Determine and Perceive Prospects’ Wants

The core of any TQM technique is a central focus on the customer. That is the number-one lesson to remove from all these approaches to whole high quality administration.

Account for customer needs when making any inner choice, whether or not that’s a course of change, a brand new service, or a characteristic replace. Take into account the way it will influence your clients. Is a brand new software program integration more likely to lead to measurable buyer success, or wind up unused and unappreciated? And do you know the reply, or are you simply guessing?

What steps can you are taking to raised perceive clients’ wants?

To begin, buyer journey monitoring can assist you higher perceive patrons’ experiences. You could perceive how they transfer by way of the assorted levels of the consideration/buying course of and turn into a long-term consumer of your product/service.

Making a map of the customer journey identifies touchpoints could contain friction. Tracking the journey tells you whether or not that friction is current and what’s inflicting it. Addressing these ache factors can enhance retention, enhance conversion, and reduce churn charges.

Let’s say that your checkout web page is unresponsive or complicated. You’ll most likely discover a better bounce charge when assessing metrics.

You would possibly check out a single-form checkout web page as an alternative, to see if it reduces frustration and improves conversions. However no matter answer you go for, the secret’s to remain targeted on the client’s perspective.

You’re not making an attempt to extend gross sales. You’re making an attempt to supply a checkout course of that’s simple and clear to your clients. The tip end result remains to be (ideally) improved income. However the distinction in mindset helps you keep away from wasted time and make solely what adjustments are wanted.

Tip #2: Place Emphasis on Buyer Satisfaction

The standard you provide to clients isn’t solely outlined by how good your services or products is. It’s a results of the entire customer experience you offer, from the primary interplay to the tenth subscription renewal.

Customer support performs a key function in serving to you exceed expectations. Distinctive service builds loyalty and retains satisfaction excessive. In different phrases, TQM might be carried out by way of high-quality communication and assist.

That stage of high quality requires expert, devoted crew members. It additionally requires supporting them with the suitable instruments. Our helpdesk Groove allows your crew to ship world-class service by way of automation options, integrations, ticket project, and self-service.

Let’s single out a key characteristic and take a more in-depth look. One strategy to apply the rules of TQM to buyer assist is by offering a self-service knowledge base:

Time is effective to clients. But when your crew has loads of tickets to answer, you would possibly want a way to assist patrons assist themselves.

Prospects simply want solutions to their questions. If they will get these solutions in an easily-accessible data base article, they save time by avoiding the necessity to attain out to assist.

By specializing in essentially the most environment friendly approach to supply the worth patrons are on the lookout for, you eradicate heaps of repetitive conversations and save time to your crew too. With Groove, you may build your own self-service resource to be as complete as clients need.

Tip #3: Accumulate Actionable Shopper-Targeted Suggestions

Any direct feedback you can obtain from your customers is gold. It enriches your improvement course of, helps you create greater buyer satisfaction, and avoids time wasted on pointless adjustments or testing.

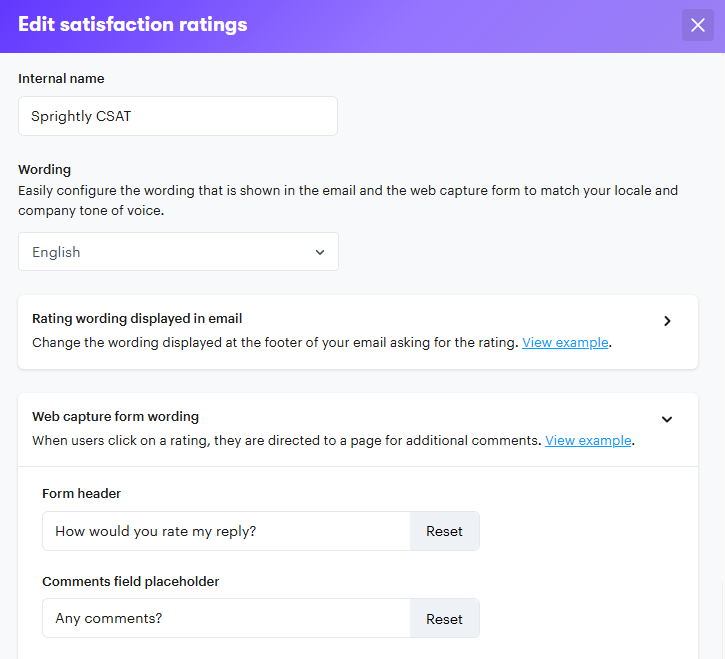

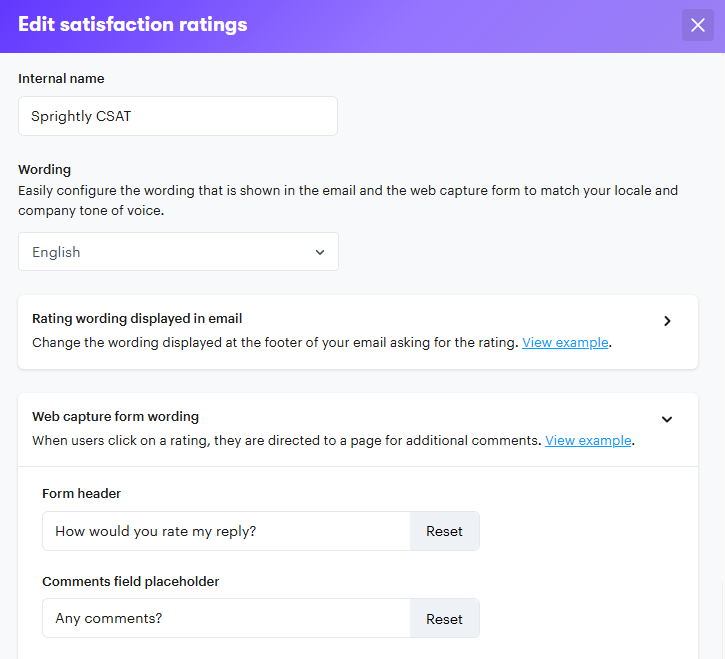

Customer surveys are an incredible place to begin. They permit for each qualitative and quantitative information assortment. Specifically, buyer satisfaction (CSAT) surveys present baseline details about how properly you’re assembly customers’ wants.

You’ll be able to simply customize and send out CSAT surveys via Groove. They are often embedded proper into your emails, making it easy for purchasers to share their suggestions by way of a numbered ranking and a free-form response choice.

All approaches to whole high quality administration depend on giving the client what they need. Survey information, focus teams, and even A/B testing are important for seeing your small business by way of your actual clients’ eyes (not the eyes of an imagined, supreme purchaser).

Understanding and Making use of The Value of High quality

The phrase “value of high quality” refers to the truth that doing issues proper the primary time prices you much less in the long term. You keep away from the necessity to redo or undo adjustments, and also you lose fewer clients as a consequence of misaligned expectations. We’ve positively learned that the hard way at Groove.

Apart from the give attention to clients, the important thing factor of TQM is the “whole” facet. You want all your workers working collectively in the direction of the identical philosophy. In the end, that issues greater than the particular taste of TQM you decide to attempt.

Groove ensures that everybody concerned in assist can collaborate effortlessly. It’s an all-in-one helpdesk answer that facilitates a TQM strategy to buyer satisfaction. Sign up for a free trial and see how!