In 1883, the violent eruption of the Krakatoa volcano in Indonesia generated essentially the most deafening sound ever recorded: it reached 310 dB, and an explosion equal to that of a cannon shot was heard three thousand miles away. The sonic wave was so highly effective that it even affected the waves in England. At present quite a few technological and scientific breakthroughs harness the potential of sound extra benignly, with functions in drugs, cleansing, or underwater echolocation. To those, we will now add 3D printing with sonic waves.

DSP: 3D printing know-how with sound waves

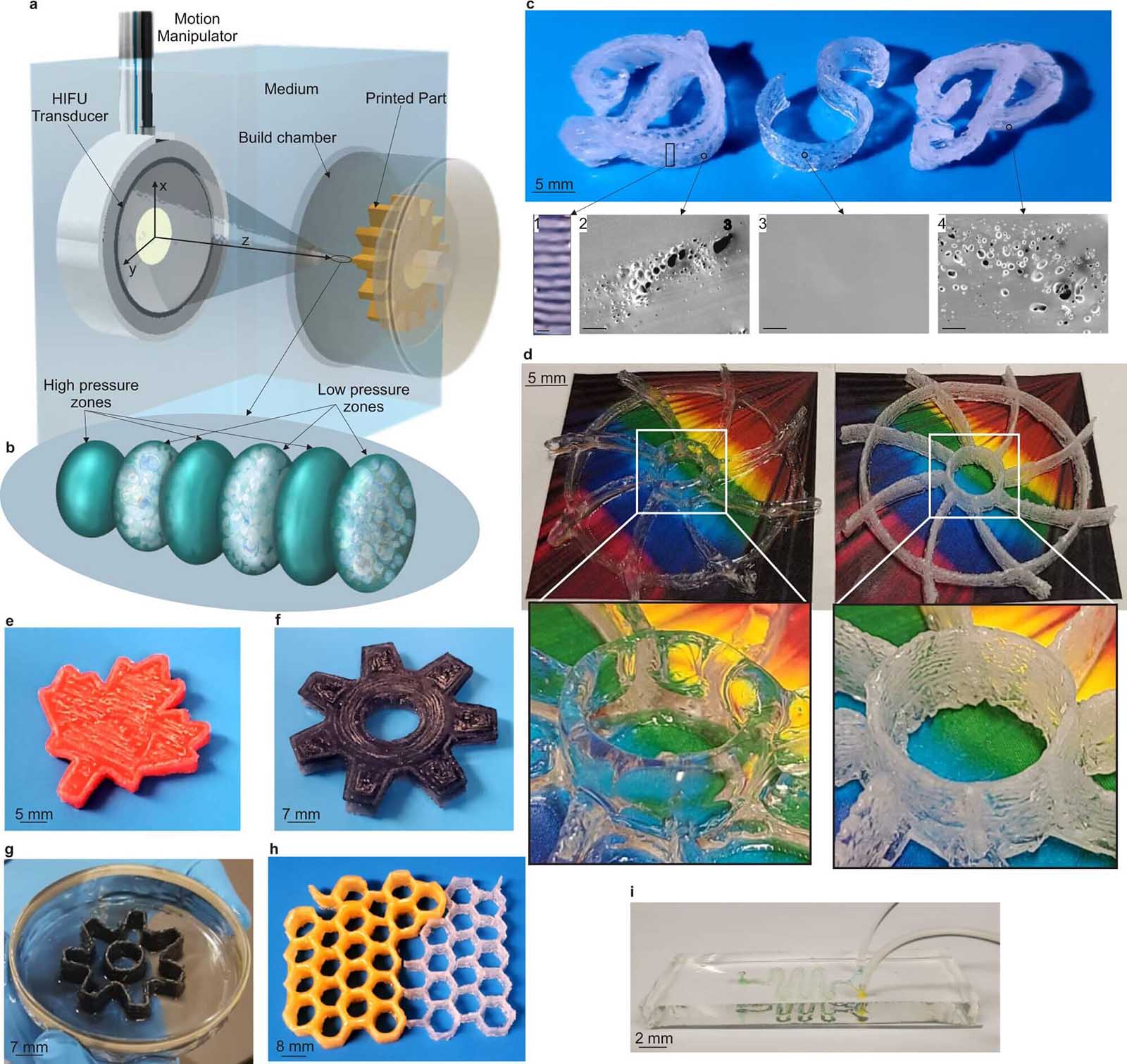

As identified by the builders of the brand new 3D printing approach, whose outcomes have been printed within the journal Nature, ultrasound had to date been utilized in damaging functions such because the removing of tumor tissue. Might or not it’s doable to make use of it for inventive functions? The quick reply is sure, as seen within the samples within the adjoining picture. As at all times, the satan is within the particulars.

There have been two major 3D printing techniques: the primary and commonest is by melting polymers or different supplies with warmth. The opposite, and fewer frequent, is utilizing light radiation, which solidifies liquid resins by means of laser beams. The third possibility is 3D printing with waves or direct sound (DSP). Furthermore, with unprecedented precision, permitting the creation of extremely advanced buildings.

The strategy utilized by researchers at Concordia University in Canada entails utilizing ultrasound at a selected wavelength to generate chemically reactive zones in a liquid polymer resolution. The sonic waves produce excessive stress adjustments in microscopic air bubbles whose temperature rises to about fifteen thousand levels kelvin for just a few picoseconds.

The uncooked materials used is a PDMS polymer generally utilized in additive printing. Nevertheless, because of the ultrasonic subject, which might be modulated relying on the liquid’s viscosity and the wavelength sort, the 3D printing course of might be carried out level by level, as in the event that they had been pixels in a picture.

The know-how, with functions within the aeronautics trade, within the manufacture of sensors and even within the printing of implants contained in the human physique, has already been examined with polymers and ceramic supplies. The following step can be to work with polymer-metal composites to attain 3D printing with waves in metals finally.

A generational leap in 3D printing with gentle and nanomaterials

As already talked about, 3D printing with gentle and resins is a considerably much less frequent approach than thermal additive printing. Nevertheless, substantial progress can be being made on this subject. Researchers at Stanford College have resorted to a blue laser beam that solidifies a gel-like resin.

Nevertheless, that isn’t all. Beneath regular circumstances, the resin solidifies alongside the complete laser beam. A further technique is required to allow selective solidification (or curing, as it’s technically identified). Scientists have achieved this by means of nanomaterials unfold throughout the resin and a crimson laser beam.

These nanomaterials are droplets of tiny dimension – one-thousandth of a human hair – and a protecting silica coating. In response to the scientists, reaching this coating to maintain the liquid inside from leaking was one of many nice challenges of the venture.

When the crimson laser beam encounters these nanomaterials, the low-energy crimson photons are transformed into high-energy blue photons. And it’s at that second that the resin solidifies, thus reaching the so-called volumetric printing.

This method is presently comparatively gradual, however its builders hope to have the ability to print a number of dots concurrently to hurry up the method and enhance the print decision.

The nanocapsules developed on this venture is also utilized in solar panels to transform low-intensity gentle vitality into usable wavelengths for photovoltaic cells.

If you wish to be taught extra in regards to the functions of 3D printing, try this text on its use in biomedicine or its rising recognition within the building sector with new biomaterials.

Whether or not by means of wave 3D printing or by resorting to new metallic alloys such because the one talked about in this article, it’s doable that 3D printing will lastly attain large-scale industrial functions quickly.

Supply: